Be responsible to nature and build the first brand of Yangtze River Cement! Green mine experience sh

In the past two years, the policy side has emphasized controllig fossil energy consumption, mainly controlling the consumption of coal, oil ad natural gas. From the current situation, want to control the total consumption of fossil energy, the important task is to promote the decline f coal and oil consumption. The National Development and Reform Commission, the Energy Board previously issued the "14th Five-Year Plan" of the modern energy system, proposed that by 2025, the proportionofnonfossil energy consumption should be increased to about 20%.

Fierce competition in the cement industry poses a new test for cement mining

The cement industry has a strong dependence on resources and is a high-risk industry, which has been recognized as a "three high" industry, i.e. high pollution, high energy consumption and high emission. At present, the entire industry is extremely overcapacity, the supply of products exceeds the demand, and producers have to rely on reducing production costs in order to survive in the fierce competition.

。Cement production begins with the acquisition of raw materials and their transportation into the plant. Mining includes stripping, drilling, blasting and other processes. No matter which process is involved, the quality of the materials received needs to be continuously stabilized, and energy saving and consumption reduction are also carried out throughout all the production processes. Taking the Dongfang Hope Mine project as an example, we would like to share the new "Green Mine Oil to Electricity Conversion, Reduce Consumption, Increase Production and Save Energy" mining technology reform program.

Industry Experts Praise Dongfang Hope Cement's "Green Wet Mining Oil to Electricity" Mining Solution

At the beginning of November this year, China Natural Resources Economics Research Institute of Mining Green Development Institute Director Yang Fan and his entourage to Fengdu Cement, research green mine construction work, learned that the company in order to achieve clean mining, energy saving, take the lead in the industry to use the "oil to electricity" wet mining drills, and the use of high and low fall potential energy, the original "stone power generation" technology, the delivery of ore not only does not consume electricity but also power generation, the research group have thumbs up, praised the company's clever use of the potential of nature, without destroying the environment, under the premise of the creation of a mine to create harmony between land and the environment, and harmony between man and nature in the mode of development.

Yang Fan said that Fondo Cement Green Mine, as a business card of Chongqing Green Mine, has set up a model of green and low-carbon transformation of mining industry. At present, the Ministry of Natural Resources is developing new acceptance standards for green mines, and Fondo Cement's green mine provides reference for the development of the new standards, and its typical practices and successful experiences are worth promoting and learning in the same industry.

图:东方希望水泥矿山

The person in charge of Dongfang Hope Enterprises said, "The company has always insisted on taking the road of ecological priority, and has made new breakthroughs in environmental protection governance. Sulfur dioxide, particulate matter, nitrogen oxides, the main cement industry emission indicators are far below the national control standards, and becomethefirsttorealizeultra-low emission of cement industry in Chongqing region, the green cement enterprises. At the same time, the plant production, living sewage to achieve zero discharge, and with the highest score of expert acceptance passed the national green mine acceptance."

"Oil-to-electric" drilling rigs revealed: centralized power source from combined high-pressure compressed air supply station

According to CementMan.com, Yang Fan, director of the Mining Green Development Institute of the China Academy of Natural Resource Economics, praised the "oil-to-electricity" drilling rig, the KS368 submersible drilling rig, which was introduced in recent years. The equipment is developed and produced by Zhejiang Kongshan Heavy Industry Machinery Co.

▲视频:油改电配套专用钻机宣传片

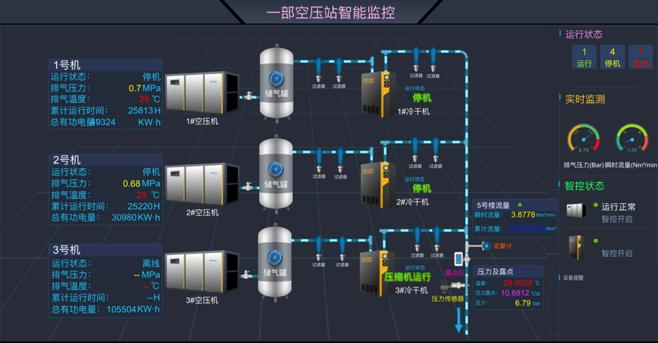

The equipment applies combined high-pressure compressed air supply station (one-stop intelligent air compressor station) as a centralized power source, replacing the traditional diesel drive, which significantly reduces the consumption of fossil energy and carbon emissions, air pollutant emissions, and improves operational efficiency.

▲图:空压站智能监控系统

Application Scenario of KS368 Down Hole Drilling Rig

Oriental Hope Mine Project

10 KS368 submersible drilling rigs

▲点击图片放大浏览

Application Scenario of KS368 Down Hole Drilling Rig

A cement mine project in Guangxi

▲点击图片放大浏览

Nowadays, how to meet the demand for cement through minimizing energy and resource consumption for social and economic development is the key to the sustainable development of the cement industry. For enterprises in the cement industry, reducing energy consumption does not only mean reducing production costs and enhancing enterprise competitiveness, but also means a responsibility and a mission. As Liu Yongxing, Chairman of Dongfang Hope Group, said: the consumption of resources by cement plants is inevitable, so we have to find ways and means to do our best to let every energy and resource give full play to its "value", which is responsible for future generations and also responsible for nature.